Welcome to our Lab Tour

Explore how we process your customized lens order.

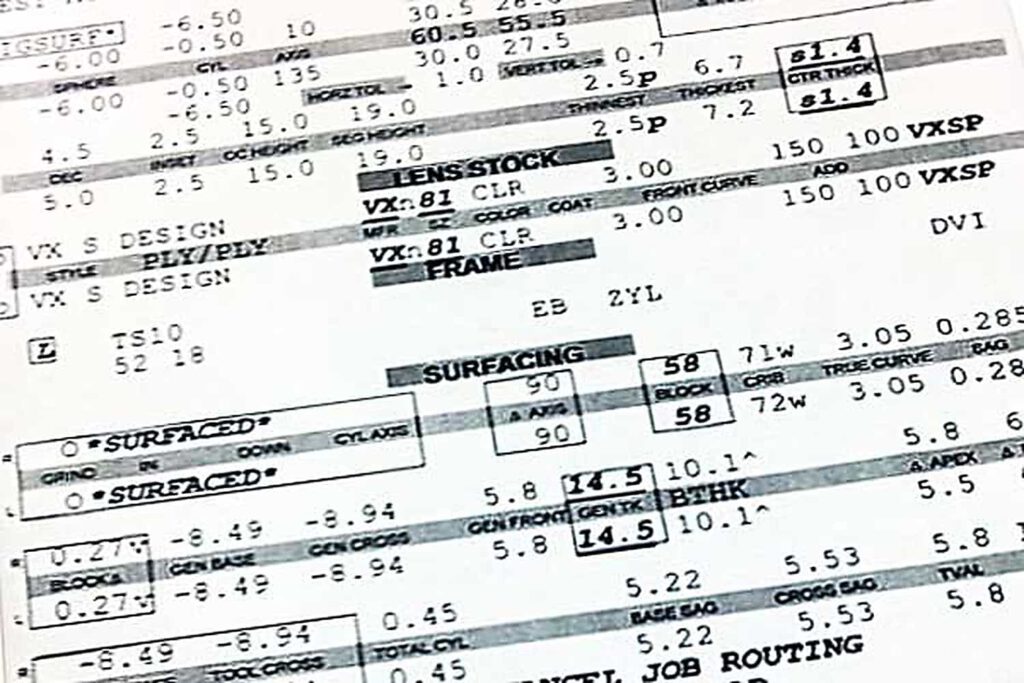

1. Your order

We receive your order online or through a fax or telephone call.

2. Every job is unique

Notice all the complex parameters used in creating a pair of customized lenses.

3. Inventory

Your work ticket is printed and moved into the inventory department. Our huge inventory of lenses allows us to fulfill 97% of orders immediately.

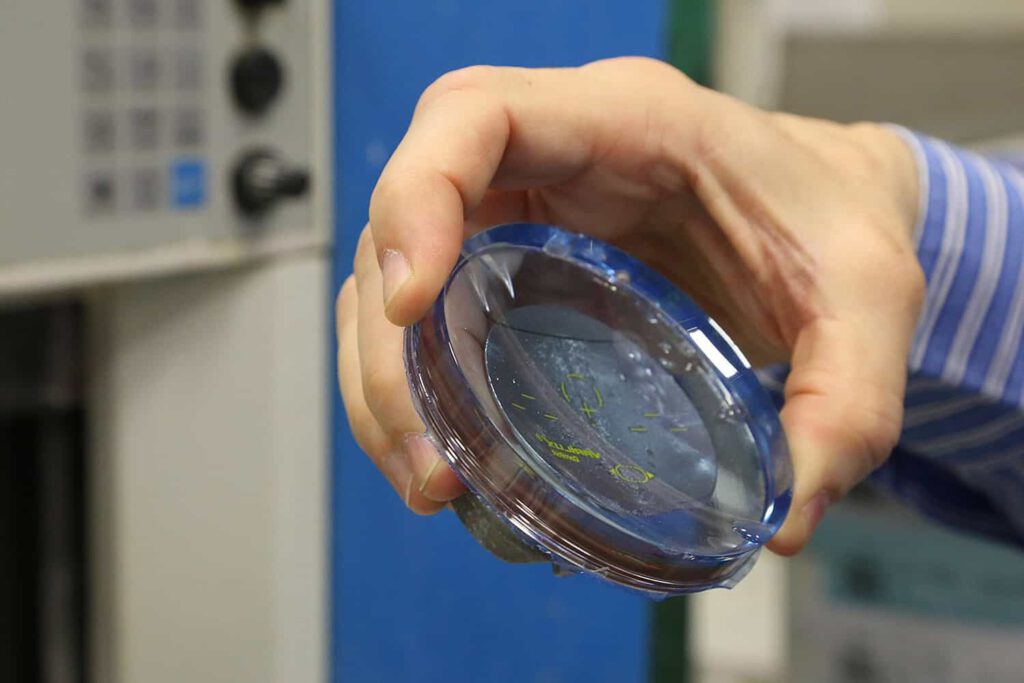

4. Lens blank

Lenses are taken out of the packaging. Notice that the lens blank starts off as a hockey puck.

5. Prep for fabrication

The lenses are prepared for the fabrication process.

6. Lens placed in “blocker”

Each lens is now placed in a “blocker” where the optics are precisely aligned to ensure correct axis and optical center placement. A block is applied to the front side of the hockey puck using a metal alloy. This block will stay on during the entire fabrication process.

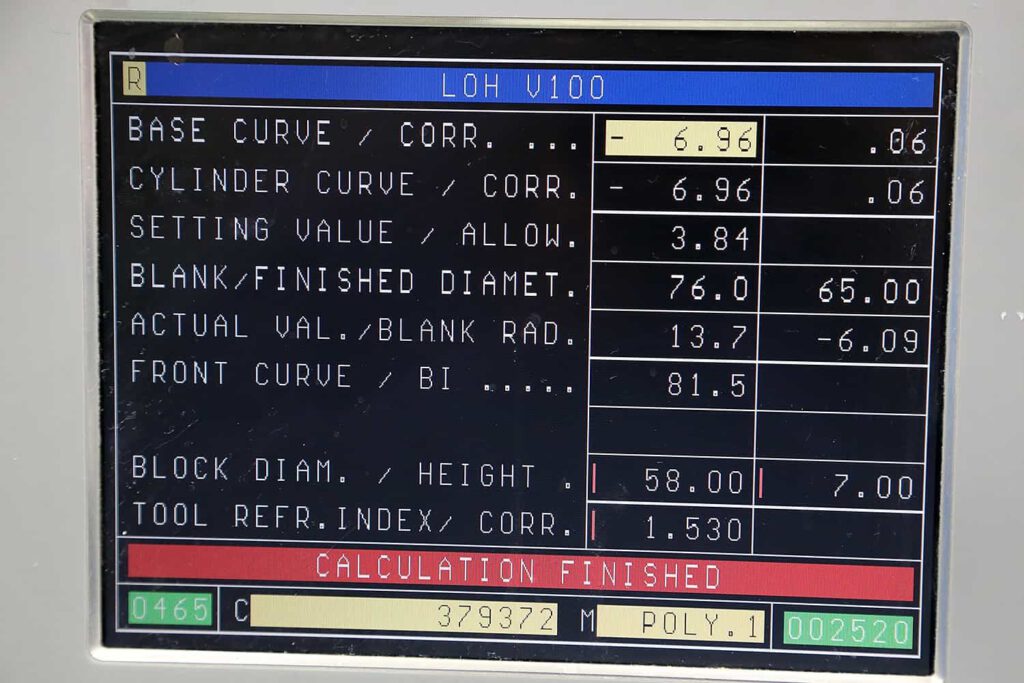

7. Traditional and digital lens fabrication

Lenses can be fabricated “traditionally,” like they have been for many years, or the new way, “digitally.” Digital lenses provide sharper and clearer vision.

8. Traditional surfacing (Traditional generating)

Traditional surfacing is limited to placing spherical and cylindrical curves on the back. Nor does it allow for any design to be surfaced on the back side of the lens.

9. Traditional surfacing (A unique hard lap)

Each traditional lens requires a unique hard lap for every sphere and cylinder combination. This equates to having thousands of hard laps on hand!

10. Traditional lenses (Fining)

Traditional lenses require a fining step to smooth the lens surface. This is achieved by using a tool called a hard lap.

11. Traditional surfacing (Polishing)

The lenses will now go to the polishing process which will restore the lens to full transparency.

12. Digital surfacing (Digital generating)

Digital surfacing allows us the flexibility to create complex progressive and single vision designs on the back side of the lens point-by-point.

13. Digital process (Digital generating)

The digital process does not require a fining step because the lenses come off of the generator with a smooth back surface. This is due to the diamond-tip point that places the design on the lens and surfaces it to exacting standards point-by-point.

14. Digitally surfaced lens (Polishing)

A digitally surfaced lens goes straight to the polishing process.

15. Digital lenses (Unique engravings)

With the digital process, we now have to place unique engravings on the back side of the lens with a laser so that you can identify the lens design.

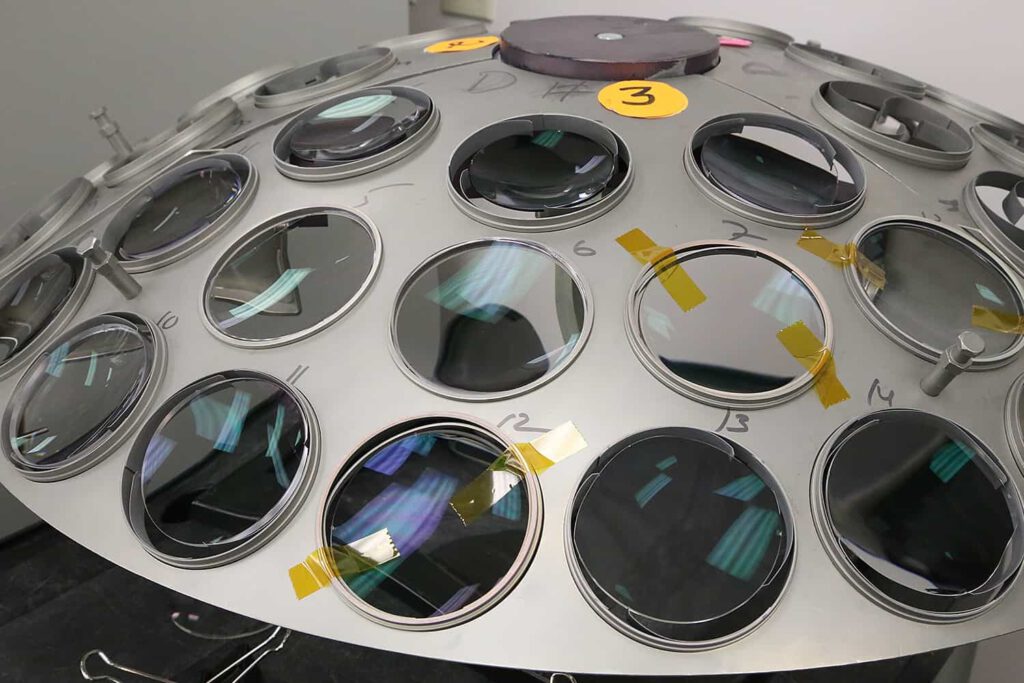

16. Coating department

Now that the lenses have been surfaced, they are ready to go into our coating department for a non-glare option such as Crizal or SharpView.

17. Lenses are inspected

Once the non-glare option is complete, the lenses are inspected. They are then ready to move to the edging department.

18. Edging Process

To start the edging process, an adhesive block is applied to the front side of the lens.

19. Computerized edgers

Our computerized edgers are programmed to the specific parameters of the frame and lens material.

20. Prep for edging

The lenses are prepared for the edging process.

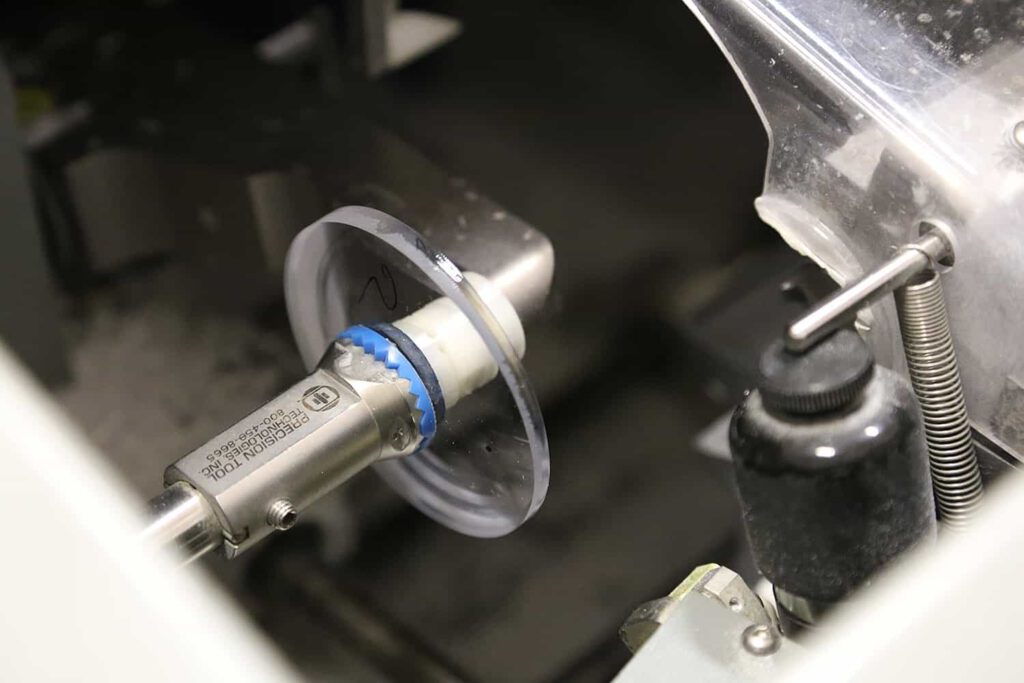

21. Lens placed on edger

The lenses are ready to be edged to match the exact shape of the frame.

22. Edging lenses

Depending upon the frame style, the lenses may have to be grooved, drilled or edge polished.

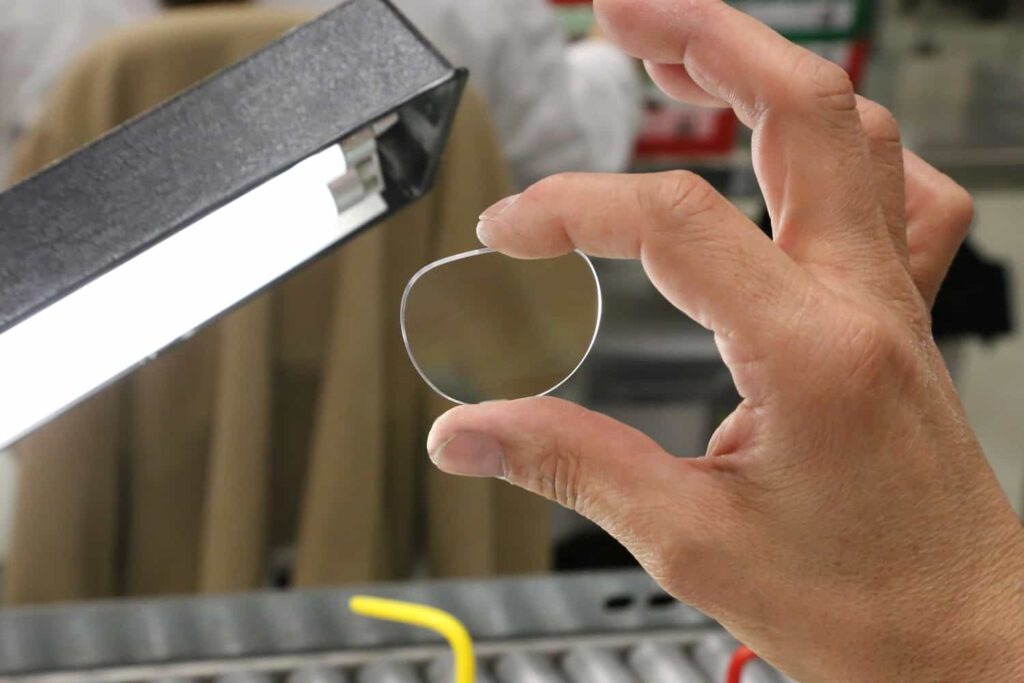

23. Lens inspection

The lenses are now inspected before being inserted into the frame.

24. Lens inserted into frame

Depending on the frame material, a plastic frame such as this one is heated and the lens is inserted. The frame is then allowed to cool so the lens is firmly seated in the frame.

25. Final inspection

The lenses are now ready for the final inspection process and are checked to verify important aspects such as the prescription, surface integrity, lens style and lens material, just to name a few.

26. Lenses are complete

Lenses are ready to be processed through our shipping department and then delivered to you.

Thank you for taking our virtual lab tour.

Please contact us if you are interested in visiting our facility in Farmingdale for a more in-depth tour.

Have Questions?

Contact us today! We’re here to help you provide the highest quality optical products to your customers.